The worldwide thirst for commercial beverages continues to grow – soft drinks, juices, bottled waters, coffee, tea, beer, cider, wines, etc. Successful beverage production requires getting the most out of raw materials and maintaining desired end-product characteristics through safe, cost-effective and sustainable multi-stage processing. HFM supplies equipment, modules and complete processing lines configured to meet the specific requirements of individual beverage producers and breweries.

Beverage

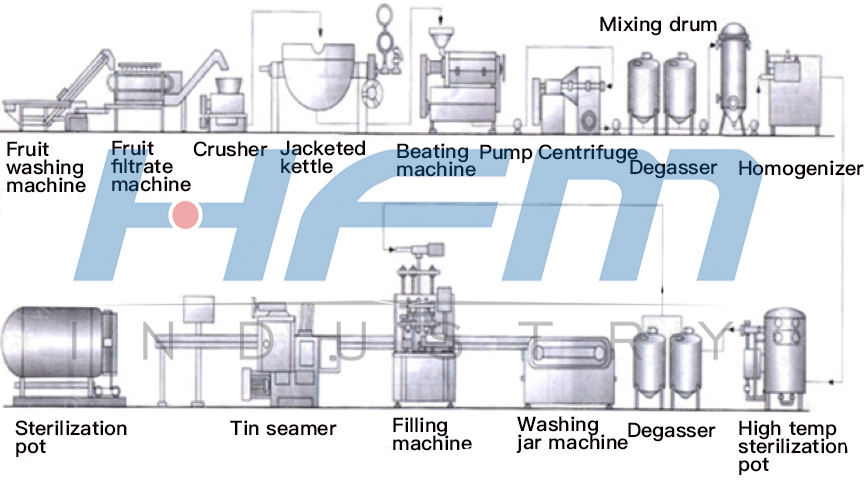

2. Process Steps

1. Raw material selection: Choose mature, fresh and intact apples. Suitable varieties are Guoguang, Hongyu and so on.

2. Cleaning and sorting: Rinse the selected fruits in a running water tank. If there is residual pesticide in the epidermis, dilute with 0.5%-1% dilute hydrochloric acid or 0.1-0.2% detergent, then strongly rinse with water. Sort and remove rotten fruit while cleaning.

3. Crushing: Use an apple grinder and a hammer crusher to crush the apples. The particle size should be the same, and the crushing should be moderate. After crushing, it is treated with a pulper to fine the particles and increase the juice extraction rate.

4. Pressing and coarse filtration: Commonly squeezed and centrifuged to extract the juice. The coarse filtration was carried out with a sieve having a pore size of 0.5mm to reduce the insoluble solid content to less than 20%.

5. Clarification and fine filtration: The method is to heat the extracted apple juice to 82–85 °C, and then rapidly cool to promote the coagulation of the colloid to achieve the purpose of clearing the juice. It can also be treated with gum, tannin, bentonite, liquid concentrated enzyme, dry enzyme preparation, and the like. The treated apple juice is clarified and filtered using a filter to which a filter aid is added. The use of diatomaceous earth as a filter layer can also remove the smell of earthworms in apples.

6. Sugar acid adjustment: Adding sugar and adding acid maintains the sugar-acid ratio of the juice at 18:1-20:1, the finished sugar content is 12%, and the acidity is 0.4%. The solid soluble content in natural apple juice is 15%-16%.

7. Degassing: The clear juice can be degassed if no concentration is required.

8. Sterilization: The juice is rapidly heated to above 90 ° C for a few seconds to achieve high-temperature instant sterilization.

9. Packaging: The sterilized juice is quickly placed in a sterilized glass bottle or tinplate canister and heat sealed. After sealing, it is rapidly cooled to 38 ° C to damage the juice’s nutrients.

3. Typical Case of Hybrid Juice Beverage Production

1. homogenization: temperature above 40 ° C, pressure 15 to 20 MPa.

2. degassing: vacuum degassing method, temperature 45 ° C, vacuum degree 0.088 MPa.

3. Sterilization: Using a plate heat exchanger, the medium is steam or hot water, and rapidly heated to 90-95 ° C for 1 minute.

4. Filling: The sterilized juice is cooled to 80 ° C or higher through a plate heat exchanger, filled into a bottle that has been sterilized and preheated, and then inverted for 10 minutes after capping.

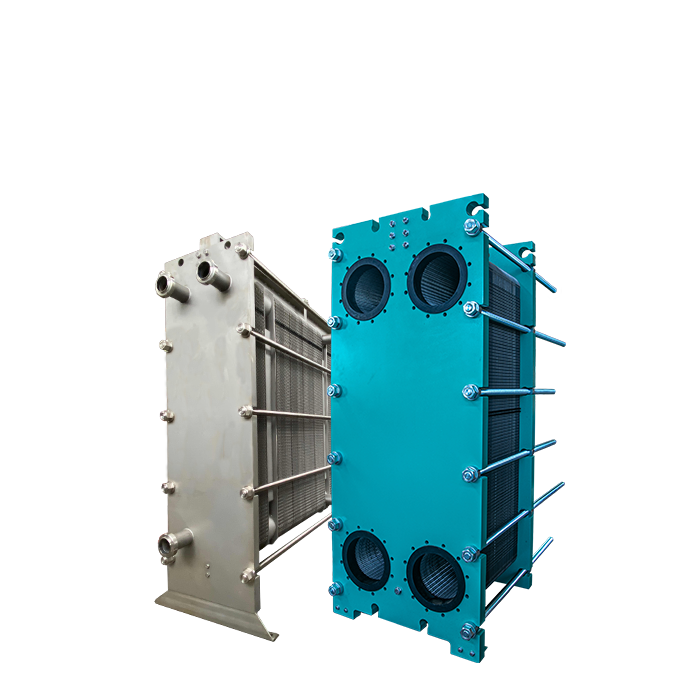

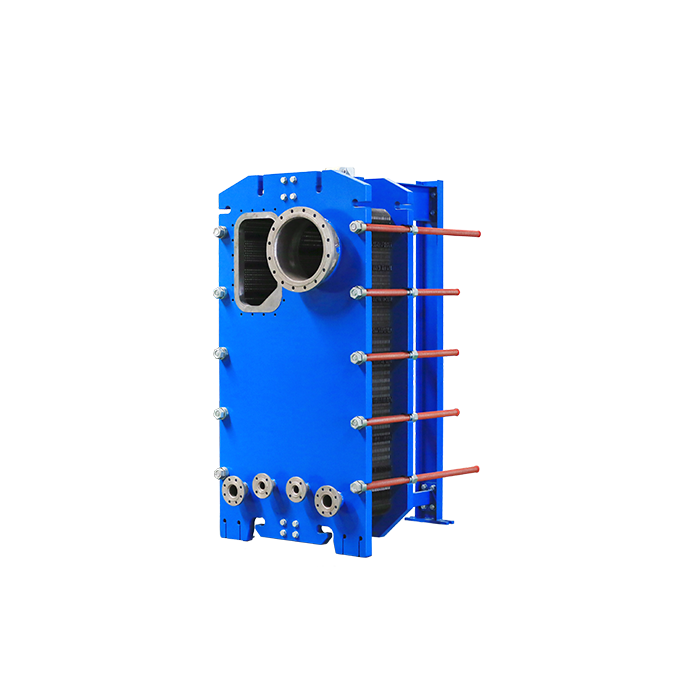

4. Plate Heat Exchanger Solution

1. Sterilization process

Hot side: water or steam inlet temperature 100 to above

Cold side: juice outlet temperature is about 90-95

Plate material: 316

Gasket: EPDM

2. Filling process

Hot side: juice: imported 90-95 outlet about 80 degrees

Cold side: water, normal temperature water

Board material: 316

Gasket: EPDM