Plate heat exchangers are widely used in a range of industrial applications to transfer heat from one fluid to another. Over time, these heat exchangers can become fouled with various types of deposits, including mineral scale, biological growth, and corrosion products. Fouling reduces the efficiency of the heat exchanger and can lead to equipment failure. Therefore, regular plate heat exchanger cleaning is necessary to maintain its efficiency and reliability.

Where is the equipment cleaned?

Gasketed plate heat exchangers can be subjected to cleaning processes either on-site or off-site, which depends on the particular equipment requirements. For expert advice on the most suitable cleaning solution for your specific gasketed plate heat exchanger, please don’t hesitate to Contact Us. Our skilled field service engineers will be glad to assist you by providing instructions or offering any other assistance you may require.

When should a GPHE be cleaned?

Maintaining clean heat exchangers is of utmost importance to ensure optimal process performance. We advise performing cleaning before the equipment becomes entirely fouled or encounters any process issues that could result in production losses or irreversible damage.

Our team at HFM is happy to provide recommendations on replacement options for your equipment, and we can also assist you with determining the optimal cleaning interval for your heat exchangers. Contact Us to learn more about how we can help you maintain your equipment’s performance.

Benefits of Regular Cleaning of Gasketed Plate Heat Exchanger(GPHE)

- Restores process equipment to optimal condition

- Minimizes maintenance downtime and labor costs

- Maintains optimal performance

- Minimizes pump energy consumption

- Reduces carbon footprint

- Prevents harmful bacteria formation, ensuring product quality and consumer safety

Therefore, it is highly recommended to incorporate regular cleaning into the maintenance plan for your heat exchangers.

Common Impurities in Plate Heat Exchangers: Mud, Scale, Oily Dirt, and Acid-Base Dirt

Prior to performing any plate heat exchanger cleaning, it is essential to conduct a thorough analysis of the internal medium and dirt present in the exchanger. This analysis will help determine the most suitable, efficient, and cost-effective method for cleaning the PHE. Common types of dirt that may be present include scale, oil, burnt matter, muddy dirt, and medium sticky matter, among others. The following section provides a general overview of some recommended cleaning approaches.

1. Mud dirt, medium adherents such as food, etc. non-adhesive dirt.

A) Mud and other impurities, such as food particles, do not strongly adhere to the plates of a plate heat exchanger, but can be easily rinsed off with high-pressure water. Tap water can be used for this purpose without any specific requirements for its quality or temperature. However, it should be noted that cooling water from open water sources may contain certain levels of sand and mud impurities.

B) Plate heat exchangers used in the food and beverage industry are prone to medium adhesion, which can be somewhat strong. In such cases, high-pressure water guns are effective for flushing the plates. Additionally, CIP (clean-in-place) methods can also be employed for thorough cleaning of the heat exchanger.

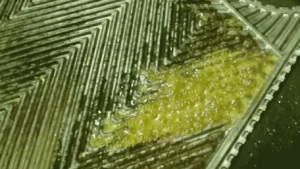

2. Scale.

Scale is composed mainly of calcium carbonate, calcium sulfate, and magnesium hydroxide, among other substances. Once it adheres to the plates, it becomes difficult to remove through simple washing. Heat exchanger cleaning chemicals are required to dissolve the scale using acidic cleaning agents, followed by rinsing. After cleaning, it is important to conduct random inspections of the plates to check for any damage, such as perforations or cracks.

3. Oily dirt.

Oily dirt is a stubborn type of dirt that results from long-term adhesion of oily substances to the plate surface. Ordinary rinsing is not effective in removing this type of dirt. Instead, soaking the plates in a degreasing agent and warm water between 25-40 degrees Celsius can effectively remove the oil.

4. Acid-base dirt.

Acid-base dirt is caused by the accumulation of acid or alkaline media on the surface of the plates over a prolonged period of time. The principle of acid-base neutralization reaction can be applied to remove this type of fouling. This involves soaking and rinsing the plates with an appropriate acid or alkaline cleaning solution.

As with other types of cleaning, it is important to conduct random inspections of the plates after cleaning to check for any damage. In addition, new technologies such as ultrasound, chemical cleaning with mechanical action, and high-pressure water jetting can also be used for efficient and effective removal of acid-base dirt.

How to Clean Plate Type Heat Exchanger

Plate heat exchanger cleaning solution

There are several commonly used PHE cleaning methods, including CIP, chemical cleaning, mechanical cleaning, and water jet cleaning. Each method has its advantages and disadvantages, and understanding the appropriate applications for each method can help ensure the long-term and effective operation of PHEs.

Common Cleaning Methods for Plate Heat Exchangers:

- Clean-in-Place (CIP)

- Chemical cleaning

- Mechanical cleaning

- High-pressure water jetting

1. Clean-in-Place (CIP) heat exchanger cleaning solution

Most PHE’s can be maintained with a clean-in-place (CIP) process, where you don’t have to open the plate pack. The biggest goal of cleaning is to flush out the various kinds of debris that collect in a PHE over time, which will vary depending on your process. Clean in place (CIP) is a cleaning method used in industries such as food, beverage, and pharmaceuticals to clean equipment such as plate heat exchangers. CIP is a cleaning method that involves circulating a cleaning solution through the plate heat exchanger in a closed-loop system.

The cleaning solution typically consists of a combination of water, detergent, and other cleaning agents, and is heated to a temperature that is sufficient to remove the fouling from the plates. The heat exchanger cleaning solution is then circulated through the plate heat exchanger for a period of time, allowing it to dissolve and remove any contaminants from the plates.

One of the key advantages of CIP is that it can be done without disassembling the heat exchanger. This makes it a faster and more efficient cleaning method than traditional manual cleaning methods, which require the heat exchanger to be taken apart and cleaned by hand. Additionally, CIP is a more thorough cleaning method, as it allows the cleaning solution to reach all areas of the heat exchanger and remove even stubborn fouling.

To clean your plate heat exchanger using CIP, first drain both sides and isolate it from your system fluid (generally done with isolation valves). Then, flush water through both sides until it runs clear. For best results, you should flush the fluids counter to the direction that they run in operation. If a lot of debris comes out, then you’re in good shape! If, however, the excessive pressure drop persists after putting the PHE back in service, or if you didn’t see many debris, then you’ll need something more aggressive than water.

The next step is to pass a cleaning agent through the PHE with a circular pump and a solution tank. The agent itself will be dictated by your process, but your PHE manufacturer can help you learn about the cleaning process in more detail if you’re unsure. You must ensure that the heat exchanger cleaning solution is compatible with the plates and gaskets of your PHE.

Chloride, for example, will almost surely corrode the plates if they’re made of stainless steel (which most are). After running the cleaning agent through your PHE, flush it with water again until both sides discharge clear. If, after putting the PHE back in service, it still runs under capacity, then you’ll need to open the plate pack and clean it manually.

In conclusion, CIP is a highly effective cleaning method for plate heat exchangers that is widely used in industries such as food, beverage, and pharmaceuticals. By circulating a cleaning solution through the heat exchanger in a closed-loop system, CIP removes contaminants and fouling from the plates without the need for manual disassembly and cleaning.

Automated CIP systems further improve the efficiency and effectiveness of the cleaning process, ensuring that the heat exchanger remains clean and efficient over time. Periodic cleaning is crucial to maintain the efficiency and longevity of the PHE and can be done with the CIP process for most PHEs. If more aggressive cleaning is needed, it’s important to ensure that the cleaning agent is compatible with the plates and gaskets of your PHE. It’s also important to follow the manufacturer’s recommendations and guidelines for cleaning, and to use appropriate personal protective equipment (PPE) when handling cleaning agents.

In addition to periodic cleaning, it’s also important to inspect the heat exchanger regularly for signs of wear or damage, such as leaks or cracks in the plates or gaskets, and to address any issues promptly to prevent further damage or contamination. Proper maintenance and cleaning of your plate heat exchanger can help ensure optimal performance and longevity, while also minimizing the risk of product contamination and equipment failure.

Unsure about which Plate Heat Exchanger to utilize?

Contact us for 1-on-1 Expert guidance and custom design services tailored specifically to your needs!

2. Chemical Cleaning

Chemical cleaning is a highly effective method for removing fouling deposits on the plates of a heat exchanger. It is especially useful for removing tough, stubborn deposits that cannot be removed by other cleaning methods. The choice of cleaning agent depends on the type of fouling present and the materials of construction of the heat exchanger.

Mild acids such as citric acid or acetic acid are often used for removing mineral scale deposits, while stronger acids such as hydrochloric or sulfuric acid may be used for tougher deposits. However, these stronger acids can be very dangerous and require special handling and safety precautions. Alkaline cleaners such as sodium hydroxide or potassium hydroxide are used for removing organic deposits.

Chemical cleaning is usually performed by circulating the cleaning solution through the heat exchanger in a closed-loop system, similar to the CIP method. The cleaning solution is heated to a temperature that is sufficient to dissolve the fouling deposits on the plates. After the cleaning solution has been circulated for a period of time, it is drained and the heat exchanger is flushed with water to remove any remaining cleaning solution and dissolved fouling deposits.

Chemical cleaning is often used in combination with high-pressure water jet cleaning for heavily fouled heat exchangers. The high-pressure water jet cleaning is used to remove the loosened deposits after they have been dissolved by the chemical cleaning solution. This combination of chemical and mechanical cleaning methods can effectively remove even the most stubborn fouling deposits from the plates of a heat exchanger.

However, it is important to note that chemical cleaning can be damaging to the plates and gaskets of the heat exchanger if not done properly. Overuse or improper use of chemicals can lead to corrosion or other damage to the materials of construction, which can reduce the lifespan of the heat exchanger. Therefore, it is important to follow the manufacturer’s guidelines and use only approved heat exchanger cleaning chemicals and procedures when performing chemical cleaning on a heat exchanger.

At present, several heat exchanger cleaning chemicals are commonly used in the industry.

Plate Heat Exchanger Cleaning Chemicals

1. Plate Heat Exchanger Cleaning Agents

Precision systems, such as special plate heat exchangers, can be disassembled for large plate replacement or chemically cleaned using a welding machine. Our PHE cleaning agent has several features, including removing inorganic salt dirt such as scale, rust, cement, and lime stains. It is also safer and more effective than most acid cleaners, with no corrosion to stainless steel under recommended conditions. This cleaning agent is specifically designed for demanding cleaning tasks, such as air conditioning heat exchanger equipment.

When using our PHE cleaning agent for welding-type whole machine chemical cleaning, please follow these steps:

1. Begin by backwashing the plate type heat exchanger. Close the inlet valve, disconnect the inlet, open the outlet valve, and rinse for 3-5 minutes to remove any unsound rust dirt and sticky mud. Kangxing clay stripping agent can also be used to remove rust slag and sludge.

2. Mix the cleaning liquid in the recommended ratio. Use a ratio of 1:5~50 when cleaning the hot water side system in a large cycle, and a ratio of 1:100~150 when cleaning the cold water side system in a large cycle.

3. Cleaning time should be completed within half an hour to 1.5 hours for cleaning in a small cycle, and within a maximum of 4 hours for cleaning in a large cycle.

4. Please use an acid washing neutralization agent to achieve a pH value of 7-8 before removing waste liquid.

5. Rinse the system thoroughly with clear water for approximately half an hour to remove all residues.

6. After filling the system with clear water, add a corrosion inhibitor and microbial killer regularly to maintain the system. Using No. 9 to protect the system from corrosion is safer and more reliable after cleaning the plate.

2. Water-based General Oil Remover for Room Temperature Cleaning

Function and Scope of Application:

This water-based general oil remover has excellent emulsification properties, especially for mineral oils such as engine oil. It is widely used for cleaning mineral oil dirt on the surface of ferrous metals and stainless steel in mechanical manufacturing, surface treatment, and maintenance. It is also suitable for cleaning hard ground, walls, equipment, and work platforms. However, it should be used with caution on aluminum or zinc and their alloys.

Features:

1. Can remove various mineral oils at room temperature, reducing equipment investment and energy costs.

2. Replaces gasoline, kerosene, and other solvents, making it safer to use.

3. Has no peculiar smell, does not volatilize gas, and does not pollute the operating environment, making it conducive to the health of operators.

4. Has powerful emulsifying properties, which thoroughly remove oil pollution with no or low residue. The cleaning effect can be improved with appropriate mechanical action such as ultrasonic cleaning.

5. Has high oil tolerance, which is more than three times higher than that of conventional water-based cleaning agents, reducing user costs and environmental impact.

6. Has strong water quality adaptability, and the usual water hardness does not affect the cleaning effect. It is low in bubbles, easy to use, and water-saving.

7. Is non-corrosive to ferrous metals and stainless steel.

8. Is phosphorus-free and environmentally friendly.

Instrument:

For items such as stainless steel or painted surfaces, protect them by referring to the recommended concentration and cleaning method in the table below.

| Recommended Concentration | 2~6% (depending on the weight of the dirt, generally: 4%) |

| Temperature | Normal room temperature (optimum temperature: 25~40 ℃, proper temperature for solid state dirt. ) |

| Cleaning method | Soaking, brush washing, ultrasonic wave, etc. (Not applicable to high-pressure spray and other ways to violently disturb the bubbles!) |

It is conducive to removing oil pollution by proper mechanical forces, but don’t mix with other cleaners!

Effective dehydration treatment is recommended immediately, such as drying after cleaning of cast iron, carbon steel, and other rust items. If effective dehydration is not possible immediately, it is recommended to do a rust-proof rinse with Wisconsin-AC1 after cleaning.

The recommended rust prevention treatment (workshop rust prevention) is to rinse the item immediately with a 4-6% Wisconsin-AC1 (water-based rust inhibitor) aqueous solution for no less than one minute after cleaning. It is crucial to clean the objects thoroughly, as the degree of cleanliness significantly affects the effect of antirust treatment.

Stability and Chemical Reactivity:

This product is stable at normal temperature and pressure. It is not compatible with strong oxidizing/reducing agents. No harmful polymerization reaction occurs.

3. Steam and condensate and pipeline corrosion inhibitor

Function and Scope of Application:

The steam and condensate pipeline corrosion inhibitor is a neutralizing amine that is used to raise the pH level of condensate and steam to a level that does not produce corrosion. It is specifically designed to prevent corrosion in steam and condensate lines, reducing water and fuel consumption and the cost of steam production. By combining with carbon dioxide in the condensate water, it removes the corrosive activity of the latter, providing an effective solution for corrosion prevention in steam and condensate systems.

Features:

The key features of the steam and condensate pipeline corrosion inhibitor are as follows:

Corrosion Prevention: The product effectively prevents corrosion in steam and condensate lines, reducing water and fuel consumption and the cost of steam production.

Alkalinity Enhancement: The neutralizing amine raises the pH level of condensate and steam to a level that does not produce corrosion.

Effective Solution: The product combines with carbon dioxide in the condensate water, removing its corrosive activity and providing an effective solution for corrosion prevention in steam and condensate systems.

Usage and Dosage:

The dosage of the steam and condensate pipeline corrosion inhibitor depends on the alkalinity of the feed water, and it is appropriate to maintain the condensate pH in the range of 8.3 to 9.0. The dosage should be adjusted as per the test results. If the steam is directly used for food processing (except for dairy products), the maximum residual concentration should not be more than 10ppm.

For optimum results, it is recommended to inject the steam lines from the split cylinder. Alternatively, the product can be poured into the boiler feed line by pulse agent feed pump directly. The agent feed pump should be linked with the boiler feed pump.

Stability and Chemical Reactivity:

The steam and condensate pipeline corrosion inhibitor is determined to be stable at normal temperature and pressure. It is impermissible for strong oxidation/reducing agents. No harmful polymerization reaction occurs. The product is safe for use and poses no harm to operators, equipment or the environment.

In conclusion, the steam and condensate pipeline corrosion inhibitor is an effective solution for preventing corrosion in steam and condensate systems. Its neutralizing amine properties enhance the alkalinity of condensate and steam, while its ability to combine with carbon dioxide in the condensate water removes its corrosive activity. The dosage should be adjusted based on the alkalinity of the feed water, and it is recommended to inject the steam lines from the split cylinder for optimum results.

4. Boiler Scale Agent

Boiler scale agent is a highly effective and safe product designed specifically for descaling boiler systems. It is especially effective at high temperatures. The product is recognized for its unique security and efficiency and is highly regarded by customers.

Features:

Powerful and safe: The product is highly effective at removing boiler scale yet is safe to use.

High temperature tolerance: The agent is especially effective at high temperatures, making it ideal for use in boilers.

Efficient: The agent is highly efficient, making it easy to use and cost-effective.

Instructions for Use:

Usage concentration: Approximately 10% of the total volume of water used in the system.

Recommended amount: Add 5 kg of the product per ton of water.

Before using the product, it is important to know the structure and material of the boiler, as well as carefully check the inlet and outlet, in order to determine the cleaning method and develop safety measures. Pretreatment should be done for any existing boiler leakage or blockage problems.

The general cleaning time takes about 6 to 9 hours, depending on the thickness of the scale. After cleaning, drain off the residual liquid and rinse the boiler with a boiler rinsing agent.

Caution:

1. Wear protective clothing and gloves when handling the product, and avoid contact with skin and eyes.

2. In case of accidental contact with skin or eyes, rinse with water immediately and seek medical attention if necessary.

3. Store the product in a cool, dry place and keep away from children and pets.

4. Do not mix the product with other chemicals, as this may cause a dangerous reaction.

5. With proper usage, the boiler scale agent is an effective and safe solution for removing scale buildup in boiler systems. It is highly recommended for use in regular maintenance and upkeep of boiler systems.

5. Safe smoke-free descaling agent

The safe smoke-free descaling agent is a highly effective product designed to remove inorganic salt dirt such as scale, rust, cement, and lime stains. It has been formulated in a special way to convert these stubborn stains into water-soluble dirt, making it easier to clean. This agent is safe to use on stainless steel, ceramics, and other materials, making it a versatile choice for a wide range of applications, including precision systems such as plate heat exchangers.

Features:

Safe and effective for removing inorganic salt dirt

No corrosion to stainless steel, ceramics, and other materials

Wide range of use, suitable for precision systems

Instructions:

1. For light rust and dirt, wash and soak the system.

2. Prepare the cleaning liquid in a ratio of 1:5-15 when cleaning the main machine.

3. Cycle the system for 4-8 hours for thorough cleaning.

4. Neutralize with acid wash neutralization agent to pH 7-8 before draining off the residual liquid to ensure effluent discharge meets national standards.

5. Rinse the system thoroughly with clear water 1-2 times to remove all residues.

6. After filling clean water, add a common corrosion inhibitor and microbial killer regularly to maintain the system.

6. Antioxidant and corrosion inhibitor

Antioxidants and corrosion inhibitors are chemical compounds that help protect metal surfaces from oxidation and corrosion. They are widely used in various industrial processes, including pickling and rinsing of systems such as plate type heat exchangers.

One of the key benefits of using antioxidants and corrosion inhibitors is their ability to prevent the formation of rust and other corrosion products on metal surfaces. This is especially important in industrial settings, where metal components are often exposed to harsh chemicals and environmental conditions that can accelerate corrosion.

When used for pickling and oxidation resistance during rinse of systems such as plate type heat exchangers, antioxidants and corrosion inhibitors offer several advantages. They help to remove any scale or rust that may have formed on the metal surfaces, while also protecting the metal from further corrosion during the rinse process. This helps to ensure that the system remains clean and efficient, which can ultimately lead to improved performance and longer equipment life.

In terms of product features, antioxidants and corrosion inhibitors are specifically designed to resist oxidation and corrosion during the rinse after pickling. They are also suitable for use in pickling systems such as plate type heat exchangers.

When it comes to application, the recommended concentration for antioxidants and corrosion inhibitors depends on the specific product being used. For example, a concentration of 1 kg of agent per 200 kg of water may be recommended, or a concentration of 5 kg of agent per ton of water may be more appropriate. It is important to follow the manufacturer’s instructions carefully to ensure that the product is used safely and effectively.

7. Compound alkaline cleaning agent (special for pasture)

Compound alkaline cleaning agents are powerful caustic soda cleaning agents designed for use in a variety of industries. Specifically, this cleaning agent is designed for use in the ranching, beer, beverage, dairy, and food processing industries. This cleaning agent offers a range of benefits, including fast and efficient cleaning, strong hard water resistance, and no corrosion to stainless steel.

One of the key benefits of this compound alkaline cleaning agent is its ability to rapidly penetrate and suspend dirt for fast and efficient cleaning. This makes it an ideal solution for use in industries where fast and thorough cleaning is essential. Additionally, this cleaning agent can be used in various cleaning ways, making it energy and time-saving.

This compound alkaline cleaning agent also offers strong hard water resistance, meaning it can effectively clean even in environments with high levels of minerals and other dissolved solids. It has a wide applicable temperature range, allowing it to be used in a variety of different settings. Furthermore, it is phosphorus-free, making it an environmentally friendly option for cleaning.

The product is a powerful caustic soda cleaning agent that is specifically designed for single-phase cleaning. It is effective in removing both organic and inorganic dirt from production systems.

In terms of technical indicators, this compound alkaline cleaning agent is a colourless to light yellow liquid with no foam. It has a pH of 12-13 in a 1% solution and contains at least 30.0% effective base (in sodium hydroxide).

This cleaning agent is compatible with a range of materials, including steel, stainless steel, and alkali-resistant plastics like PC, PE, PP, PTFE, PVDF, and PVC. When used under the normal recommended use conditions, this cleaning agent will not corrode stainless steel or other compatible materials.

When it comes to application, this compound alkaline cleaning agent is suitable for use in any automatic cleaning and CIP process in any water hardness conditions. For example, in the brewing and beverage industry, it can be used to clean tanks, pipes, filters, and storage tanks at a concentration of 0.5-3.0% and normal temperature to 80℃, with cleaning time depending on the circumstances.

In the dairy industry, it can be used to clean cheese ripening cylinders, tanks, and pipelines at a concentration of 0.5-2.0% and temperatures ranging from 50℃ to 80℃, again with cleaning time depending on the specific situation.

For passivation precleaning, this compound alkaline cleaning agent can be used for 1 to 3 hours at normal temperature to 85℃ and 9 to 12% of the concentration used, followed by thorough rinsing. For PC barrel/bottle cleaning, it can be used for 1-2 minutes at temperatures ranging from 40 to 80℃ and 0.5-1% of the concentration used. This makes it an ideal solution for heavy sewage bottles under hard water quality conditions.

8. Special detergent for milking equipment (acid)

This product is a composite acid made primarily of phosphoric acid and sulfuric acid. It is designed to remove inorganic salts such as calcium and magnesium that cannot be removed by alkaline detergents. It is suitable for removing milk scale and dairy stone in milking equipment.

Scope of Application:

It is suitable for cleaning pipes, milk buckets, and milk storage tanks of both large and small milking machines.

Product Features:

This product has low corrosion to equipment, which helps to prolong the service life of the equipment and reduce depreciation rates. Its composite acid formulation, which includes a corrosion mitigation component, results in a minimal corrosive effect on the equipment’s metal parts. It produces no foam and has strong cleaning ability, reacting violently with calcium and magnesium salts, making it effective for removing scale. It can also remove rust spots from the equipment.

Instructions:

The recommended use ratio is 0.4% to 1%, and it should be diluted with deionized water at 55 to 60℃. For best results, use a cycle cleaning method for 8-10 minutes or soak for 20 minutes. The discharge water temperature must be no less than 40℃ after circulating cleaning. After cleaning, rinse thoroughly with clean water to neutralize the acid.

Notes:

1. This product should not be mixed with alkaline detergents that contain chlorine, as doing so may release toxic chlorine gas. The raw liquid of the product may corrode stainless steel, so it should not be used directly.

2. Rubber gloves and protective glasses are required during operation.

3. In case of accidental contact with eyes, rinse immediately with cold water for at least 15 minutes. In case of accidental ingestion, wash the mouth and drink 1-2 cups of water or milk to induce vomiting. In case of inhalation, move to a fresh air section immediately and seek medical advice in serious cases.

4. Keep the product out of reach of children.

5. During storage and transportation, avoid exposure to light, heat, and pressure.

3. Mechanical Cleaning for plate heat exchanger

Manual cleaning steps are an essential part of maintaining plate heat exchangers (PHEs). However, in cases where the fouling is too severe or if other cleaning methods have failed, mechanical cleaning may be necessary. Mechanical cleaning of PHEs involves disassembling the heat exchanger and manually cleaning the plates. Here are the general steps involved in mechanical cleaning:

Isolate the PHE:

Turn off any flow and isolate the PHE from the system by closing the isolation valves.

Disassemble the PHE:

Carefully disassemble the heat exchanger by removing the tie bolts, then separating the plate pack and gaskets. The first step in maintaining the heat exchanger is to disassemble the plate heat exchanger, which requires professional mechanics to shut off all fluids entering and leaving the heat exchanger (need to ensure that lockout procedures are followed). To be able to remove fluid from the heat exchanger, you need to release all pressure by opening the valve.

You will want to finish cooling before the heat exchanger opens, to do this you will need: Loosen the acid on the heat exchanger, about 1/4 ft. at a time, before moving the next bolt. To ensure effective bolt loosening, do not over loosen the bolt as it may damage the bolt head. After removing the bolts, slide each removable head back to expose the hot plate pack. To facilitate reinstallation, all boards need to be numbered in reverse order, and the number needs to be displayed on the top of each board.

Remove the plates:

Remove each plate from the plate pack and scrub them with a soft-bristle brush, such as a nylon brush, to remove the fouling. Follow the steps below to make sure you don’t miss any steps: First, remove the gasket. The gasket can be reused or not based on its current condition. To check if your gasket is still in pristine condition, just pinch it to know its condition.

If you need to reuse the gasket, wash them with soap and water, then hang them in a clean, dry area. If there is loose debris on the board, then it needs to be cleaned with soap, water, and a soft brush or pressure washer, not a grinder or a hard brush. Clean the plate until all debris is removed. The groove of the gasket needs to be very careful and in very severe cases hot acid and caustic need to be used to break down stubborn adhesives and buildup.

Clean the gaskets:

Clean the gaskets using a soft cloth or sponge with a mild cleaning solution to remove any residue and contaminants.

Reassemble the PHE: Reassemble the PHE by replacing the gaskets and plates in their original order, then reinsert the plate pack between the end plates and tighten the tie bolts. Before inspecting and preparing heat exchanger plates, the plate frame must be cleaned and prepared before reassembly: Start by inspecting the nozzle area, paying close attention to weld areas where corrosion and defects may occur.

Check the straightness of the fixed head and movable head with a ruler. For painted and powder-coated carbon steel frames, the coating needs to be inspected to determine if it is in satisfactory condition. Check the connection points of the upper and lower rails. Polishing may interfere with serious defects in the sheet.

Test the PHE:

Once the PHE has been reassembled, test it by running water or a low-viscosity fluid through it to ensure that there are no leaks. During this inspection, it is critical to test and inspect your boards for cracks and pinholes throughout the facility. Visually inspect the heat exchanger for defects, paying close attention to where the plates touch areas to make sure they are not losing or misaligned. Check the pressure drop and flow rate to ensure that they are within the recommended range.

Reinstall the PHE:

After the PHE has been tested and confirmed to be working properly, reinstall it back into the system. Make sure to open the isolation valves slowly to avoid any water hammer or damage to the heat exchanger.

Perform post-cleaning checks:

After the PHE has been reinstalled, perform post-cleaning checks to ensure that the heat exchanger is functioning properly. Check for any leaks, pressure drops, or other abnormalities in the system. Monitor the performance of the heat exchanger over time to ensure that fouling does not occur again.

It is important to note that mechanical cleaning should only be performed by trained professionals to ensure that the heat exchanger is not damaged during the cleaning process. Additionally, regular maintenance and cleaning of the heat exchanger can help prevent severe fouling and the need for mechanical cleaning.

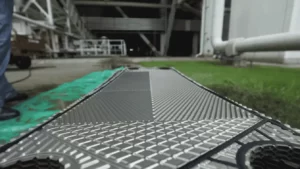

4. High-pressure Water Jet Cleaning for Plate Heat Exchanger

High-pressure water jet cleaning is a heat exchanger cleaning method that involves using a high-pressure water jet to remove fouling from the plates of a plate heat exchanger. This method is particularly effective for removing soft deposits, such as biofilms, which are thin layers of bacteria that can accumulate on the surfaces of the plates.

The water is typically sprayed onto the plates at a pressure between 1000-2000 psi, which is strong enough to break up the deposits and wash them away. High-pressure water jet cleaning is suitable for use on most plate materials, including stainless steel, titanium, and nickel alloys.

One of the advantages of high-pressure water jet cleaning is that it can be a relatively fast and efficient heat exchanger cleaning method. It can be done without disassembling the heat exchanger and can be a useful method for removing soft fouling from the plates. However, it may not be effective for removing hard deposits, such as mineral scale, which may require more aggressive cleaning methods.

It is important to note that when using high-pressure water jet cleaning, care must be taken to avoid damaging the plates or gaskets of the heat exchanger. This can be done by using the appropriate pressure and by ensuring that the water jet is not directed at the edges of the plates or at the gasket areas.

Equipment for Plate Heat Exchanger Cleaning Solution

In this context, different types of equipment are used for plate heat exchanger cleaning.

High-pressure water jetting equipment is one of the most commonly used equipment for plate heat exchanger cleaning. It is used to deliver water at high pressure to remove deposits from the heat exchanger plates. The equipment includes high-pressure pumps, hoses, and nozzles that can deliver water at pressures up to several thousand psi. The high-pressure water jetting method is effective for removing soft to moderate fouling deposits from the heat exchanger plates.

Chemical cleaning equipment is used when high-pressure water jetting alone is not sufficient to remove the deposits. The equipment includes tanks, pumps, and hoses for circulating cleaning agents through the heat exchanger. The cleaning agents can dissolve deposits and remove them from the plates. The chemical cleaning method is effective for removing hard and stubborn fouling deposits that cannot be removed by water jetting alone.

Mechanical cleaning tools such as brushes, scrapers, and other tools are used to physically remove deposits from the plates. These tools are especially useful for hard deposits that cannot be removed by water jetting or chemical cleaning alone. The mechanical cleaning method is also effective for removing deposits from areas that are difficult to reach by high-pressure water jetting or chemical cleaning.

Inspection equipment such as cameras and borescopes are used to inspect the plates for fouling and damage before and after cleaning. This helps to determine the effectiveness of the cleaning process and identify any potential issues that need to be addressed. The inspection equipment is also useful for identifying any areas that require extra attention during the cleaning process.

In summary, the equipment used for plate heat exchanger cleaning includes high-pressure water jetting equipment, chemical cleaning equipment, mechanical cleaning tools, and inspection equipment. Each type of equipment has its advantages and disadvantages, and the choice of equipment depends on the type and severity of fouling deposits and the condition of the heat exchanger plates. A combination of different cleaning methods may be necessary for effective and thorough cleaning of the heat exchanger plates.

For more equipment introduction regarding Plate Type Heat Exchanger Cleaning Solution, check out HFM Youtube Channel for more information.

Top 10 Tips to Keep Your Plate Heat Exchanger In Top Condition

The following guidelines are recommended to ensure optimal operation of a plate heat exchanger:

1. Verify that operating conditions, such as temperature and flow, are consistent with design specifications.

2. When starting up, vent the heat exchanger and gradually open and close the valve to prevent pressure fluctuations and water hammer.

3. Utilize upstream filters and strainers to remove particulate fouling and safeguard the heat exchanger.

4. Perform daily checks for variations in temperature, pressure, and any indication of external leaks.

5. Regularly clean and lubricate the fastening bolts.

6. Use condition detection technology to assess the heat exchanger’s status, avoiding the need to open it for inspection.

7. Implement clean-in-place (CIP) procedures to eliminate the necessity for opening the heat exchanger for cleaning.

8. Keep spare equipment clean and dry, and flush the heat exchanger with fresh water and drain it entirely if it is out of service.

9. Protect the heat exchanger from water splashes and avoid exposure to UV rays and ozone that may be generated by the power supply.

10. Maintain a stock of critical spare parts and adhere to the manufacturer’s storage instructions.

Upgrade your plate heat exchanger to a brand new one with HFM Plate Heat Exchanger! If your current one is beyond repair or cleaning, or in a condition too severe to salvage, trust the experts at HFM PHE to provide you with the best upgrade solution.